The Science of Quality: An Inside Look at AntennaGear’s Testing Process

Posted by Gordon Reed on 23rd Jul 2025

Quality You Can Count On

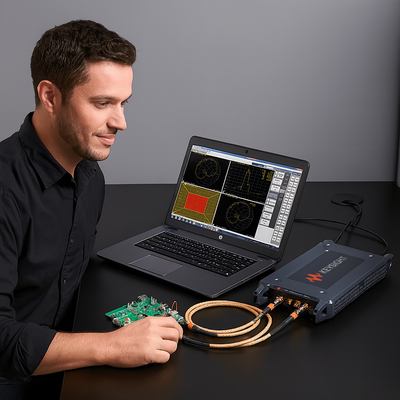

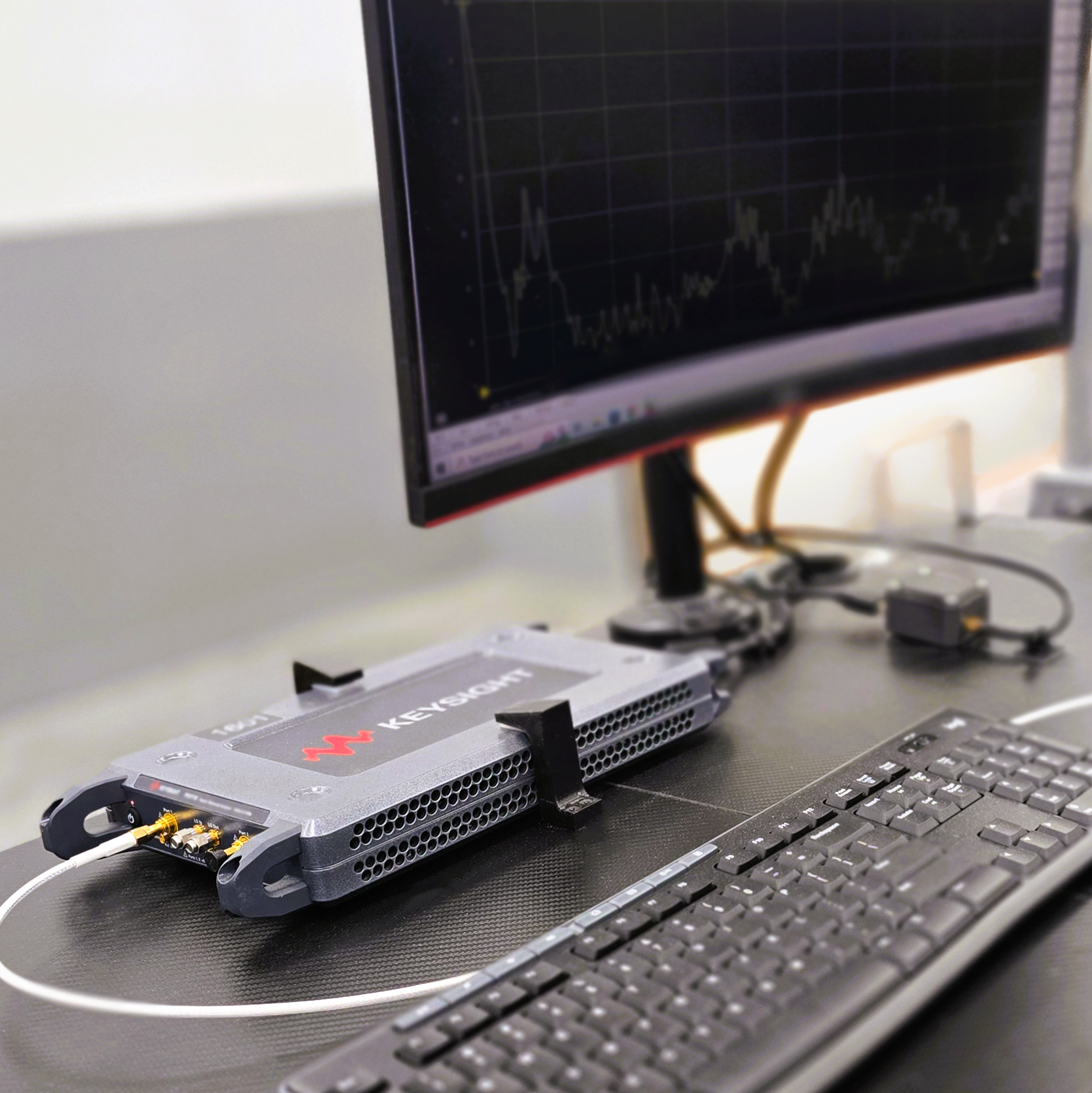

In the world of RF engineering, even minor inconsistencies can degrade performance and reliability. At AntennaGear, we believe quality control isn’t a step, t’s the foundation of our entire assembly process. Unlike manufacturers that test a sample from each batch, we test every single antenna that comes off our production line. Our tools of choice? Keysight's P9372B Vector Network Analyzer (VNA), a benchmark for precision in the RF industry. This is not a sponsored mention; we simply trust Keysight’s standard of excellence in RF testing equipment.

VNA Testing: The Definitive Standard for RF Validation

A Vector Network Analyzer (VNA) is a cornerstone instrument for characterizing RF components. For antennas, the VNA provides key insights into:

- S11 (Return Loss): Verifying how effectively the antenna radiates power instead of reflecting it.

- VSWR (Voltage Standing Wave Ratio): Ensuring minimal signal reflection for optimal energy transfer.

- Impedance and Bandwidth: Confirming that the antenna resonates accurately across its intended frequency range.

Batch sampling can miss defective units. A single mistuned antenna can fail to meet gain or bandwidth requirements, leading to dropped connections and poor network performance. AntennaGear avoids these pitfalls by testing every unit individually.

Keysight’s Streamline Series P9372B: Lab-Level Accuracy on the Assembly Floor

Keysight is synonymous with RF precision. The Keysight P9372B from the Streamline Series brings advanced lab-grade testing to a compact, production-ready format. Key highlights include:

- 2-Port Coverage from 9 kHz to 9 GHz – Ideal for testing modern multi-band antennas.

- High Dynamic Range (up to 115 dB) – Provides precise reflection and transmission measurements.

- Low Trace Noise (0.0015 dB rms at 10 kHz IFBW) – Ensures clean, repeatable data for every test.

- Compact USB Architecture – Lightweight and perfect for high-throughput production environments.

AntennaGear’s QC Workflow: Every Antenna. Every Time.

Our testing protocol is designed to catch even the smallest deviation from design specifications:

- Post-Assembly Inspection – Physical and structural review.

- VNA Testing of Every Antenna – Full S-parameter sweep across required frequency bands.

- Fine-Tuning Adjustments – Any unit slightly off-target is re-tuned before approval.

- Final Quality Certification – Each antenna is verified to meet return loss, VSWR, and impedance benchmarks.

This hands-on, unit-by-unit approach ensures there are no weak links in our product lineup.

Why Testing Benefits You

- Guaranteed Consistency: No guesswork, no variance between antennas.

- Field-Proven Reliability: Lower failure rates and optimized performance for mission-critical systems.

- Enhanced Value: Customers receive only antennas that have been fully certified for RF excellence.

- Future-Proof Readiness: Testing at up to 9 GHz ensures readiness for 5G, Wi-Fi 6/7, and beyond.

Keysight + AntennaGear = Precision in Every Connection

By integrating Keysight’s P9372B VNA into our assembly line, AntennaGear brings laboratory-grade testing directly into our production environment. This guarantees our customers receive antennas that are meticulously tuned and validated, every time.

What This Means for You

When you choose AntennaGear, you’re not just buying an antenna, you’re investing in performance proven by industry-leading Keysight testing equipment. Explore our product lineup at AntennaGear.net and experience the difference.