Inside AntennaGear: Precision RF Antenna Engineering, Prototyping, and In-House Assembly

Posted by Gordon Reed on 30th Jun 2025

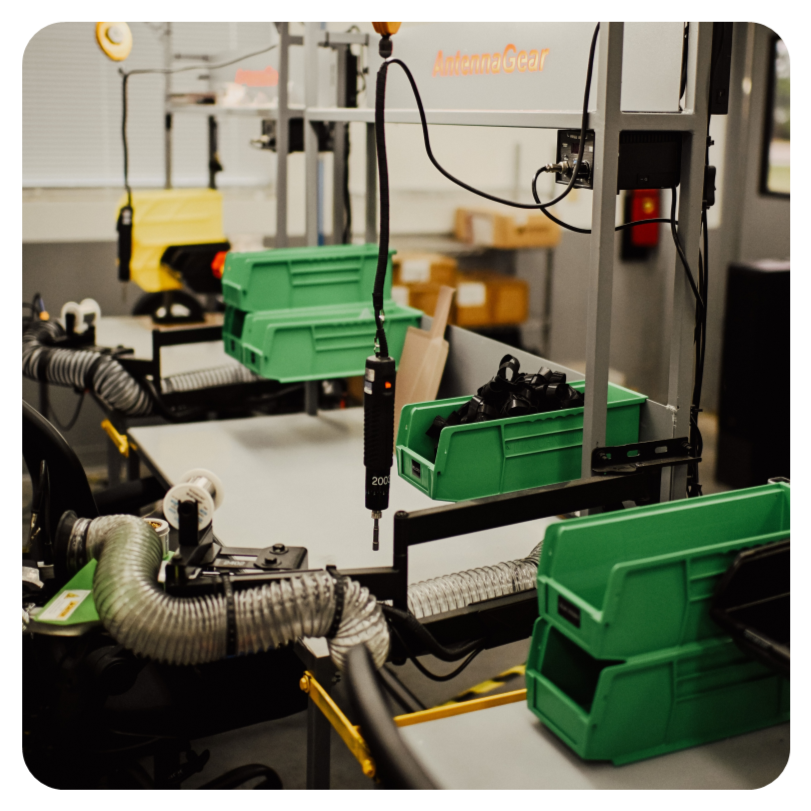

At AntennaGear, we’ve built more than antennas—we’ve built a process. By keeping engineering, prototyping, and production entirely in-house, we ensure tight control over quality, faster lead times, and the ability to rapidly adapt to customer-specific requirements.

At the heart of this operation lies our proprietary antenna assembly line, uniquely designed for precision, efficiency, and consistency. From RF concept to cable termination, our vertically integrated approach delivers antennas engineered for peak performance—assembled with purpose.

Engineering at the Core: Performance-First Antenna Design

It all begins with design. AntennaGear’s RF engineering team brings deep expertise in cellular (4G LTE, 5G), Wi-Fi (including Wi-Fi 6E and Wi-Fi 7), GPS/GNSS, and CBRS antenna systems. We leverage advanced electromagnetic simulation tools to model radiation patterns, isolation, and impedance characteristics before a single physical part is built.

Every design is guided by real-world deployment goals, whether for an enterprise-grade mobile router, a mission-critical gateway, or an industrial IoT node. Our engineers balance electrical and mechanical requirements to ensure the final solution integrates seamlessly into the device and performs flawlessly across its intended environment.

Rapid Prototyping: From CAD to Field Test

Our in-house prototyping lab accelerates the transition from concept to validation. Using 3D printing, CNC machining, and rapid-turn PCB production, we test multiple configurations quickly allowing for iterative improvements and real-world testing before full-scale production.

Each prototype undergoes lab and field validation across key metrics: VSWR, gain, port-to-port isolation, and ruggedness under stress. This tight feedback loop between engineering and prototyping reduces development cycles and produces better, deployment-ready results.

Specialized In-House Assembly: Where Precision Meets Production

Unlike generic contract manufacturing, AntennaGear’s custom-designed antenna assembly line is purpose-built to handle the complex demands of modern multi-lead, multi-band antenna systems. Our proprietary tooling and workflow are designed for:

- High-precision cable termination and lead bundling with a wide array of RF terminations including SMA, FAKRA, QMA, TNC, N-Type, and many others.

- Secure mechanical fastening and potting for vibration and weather resistance

- Streamlined output with minimal handling errors

This isn’t a one-size-fits-all line, it’s a highly adaptable system optimized for high-mix, mid to high volume production while maintaining tight tolerances and repeatability.

Quality and Efficiency Through Proprietary Equipment

Our proprietary equipment enables:

- Automated cable prep and stripping for consistent dielectric exposure and minimal signal degradation

- Custom fixtures and jigs that ensure precise alignment, sealant application, and connector seating

- Lead-specific bundling and labeling systems that reduce field installation time and user error

- Integrated quality control stations, where every antenna is tested for signal continuity, impedance match, and lead mapping accuracy

We deploy network analyzers and TDR systems at key checkpoints to ensure that each unit meets both electrically and physically—before it leaves our facility.

Custom Cable Finishing and Lead Management

Our in-house cable finishing and labeling department separates us from commodity suppliers. We can quickly deliver:

- Custom cable lengths for any application

- Specific connector types, polarities, or angles based on device clearance and installation needs

- Labeled, field-deployable leads to multi-MIMO setups—making it easy for installers to match ports with confidence

This flexibility enables us to tailor antenna kits for specific router models, configurations, and mounting constraints—without compromising performance.

Scalable, Field-Ready Antenna Solutions

By managing the entire process—from simulation to soldering, AntennaGear produces antennas that are consistent, rugged, and ready for deployment at scale. Our customers benefit from:

- Reduced lead times

- Higher performance consistency

- Simplified installation and routing

- Fewer support issues and improved field success rates

Whether it’s a three-lead antenna for an IoT device or a twenty-one lead solution for a mobile enterprise router, every cable is routed, terminated, and tested with purpose.

Designed, Built, and Proven In-House

AntennaGear’s end-to-end control over engineering, prototyping, and production gives us—and our customers—a critical edge. Our proprietary antenna assembly line isn’t just a manufacturing asset; it’s a performance engine. By combining precision design with tightly controlled production, we deliver solutions that meet the demands of industrial, mobile, and enterprise environments—every time.

Need a custom antenna solution built for performance and engineered for scale?

Contact the AntennaGear Solutions Team today to start your project.